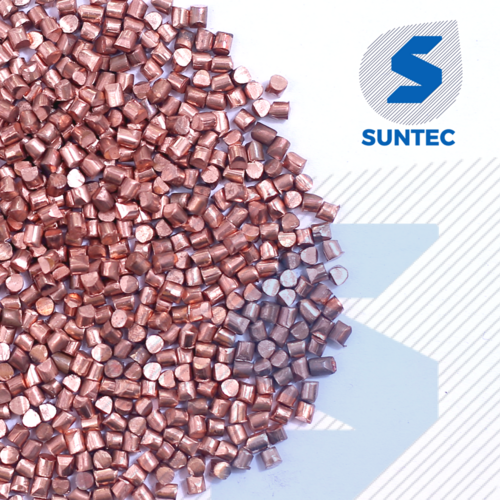

Copper Cut Wire Shot

Price 650 INR/ Kilograms

Copper Cut Wire Shot Specification

- Finish

- Clean, Bright

- Condition

- New

- Surface Treatment

- Polished, Deburred

- Diameter

- 0.5 mm to 3.0 mm

- Size

- 0.5 mm to 3.0 mm diameter available

- Origin

- India

- Product Type

- Copper Cut Wire Shot

- Shape

- Cylindrical, As Cut or Conditioned

- Strength

- High tensile strength

- Alloy

- Copper (99% minimum pure or as per requirement)

- Grade

- IS 191 (Standard), Customized grades on request

- Length

- As per requirement (cut to exact size)

- Color

- Copper (Metallic Red)

Copper Cut Wire Shot Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- FOB Port

- Faridabad , Haryana

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- Kilograms

- Delivery Time

- Months

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Standard

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About Copper Cut Wire Shot

In order to comprehend and respond to the diverse requirements of honorable patrons, we are able to offer a superior range of Copper Cut Wire Shot. The offered range is made utilizing premium grade raw material, which is sourced from reliable vendors of the market. Along with this, the offered range is tested on different characteristics to ensure its adherence with the industry laid norms and standards.

Features:

- Durable

- High thermal conductivity

- Ability to withstand harsh conditions

Technical Specifications :

|

Copper |

|

|

Size |

2.50 mm, 3.00 mm |

|

Brand |

Suntec Enterprises |

|

Hardness |

180-205 HV. |

|

Density |

8.60 g./cc. |

|

Chemical Composition |

Cu 99.0% |

|

Packaging Type |

PP Bag |

|

Tensile Strength |

1650-2050 Mpa |

|

Minimum Order Quantity |

1000 Kilogram |

Precision Manufacturing for Diverse Applications

Our Copper Cut Wire Shot stands out due to its customizable length and high purity alloy content. Each piece is meticulously cut and conditioned, followed by an advanced deburring and polishing process, ensuring a bright and clean finish. This versatile product is engineered for optimal strength, making it suitable for demanding applications in surface preparation, shot peening, and metal finishing.

Reliable Quality Backed by Standards

Compliant with IS 191 standards, our copper shots guarantee consistent quality and performance. We prioritize stringent quality checks throughout production, using top-grade copper sourced in India. Whether you need standard sizes or specific customizations, our facility accommodates all requirements promptly, ensuring you get the right solution for your industrial needs.

FAQs of Copper Cut Wire Shot:

Q: What is the main application of Copper Cut Wire Shot?

A: Copper Cut Wire Shot is primarily used for shot peening, surface cleaning, deburring, and finishing in a wide range of industries, including automotive, aerospace, and electronics. Its high tensile strength and polished finish make it ideal for improving fatigue life and achieving precise surface treatments.Q: How is the length and diameter of the wire shot customized?

A: Lengths are cut precisely as per customer specifications, ensuring a perfect fit for each application. Diameters are available from 0.5 mm to 3.0 mm, with both as cut and conditioned shapes, allowing tailored solutions for varying industrial needs.Q: What surface treatments does the copper shot undergo?

A: Each copper shot receives a professional polishing and deburring process, resulting in a clean and bright metallic red finish. This treatment enhances shot performance, minimizes damage to workpieces, and ensures uniform results during use.Q: Where are your copper cut wire shots manufactured and supplied from?

A: Our copper cut wire shots are produced and exported directly from India, adhering to international quality standards and efficiently serving global markets as a trusted manufacturer and supplier.Q: What are the key benefits of using high-purity copper wire shots?

A: The high purity (minimum 99% copper) ensures excellent conductivity, ductility, and minimal contamination. These properties make our copper wire shots effective for sensitive applications, providing reliable results and extended media life.Q: Can you provide customized grades and finishes for specific requirements?

A: Yes, we offer copper shots in IS 191 (Standard) as well as customized grades and finishes to accommodate unique project demands. Customers can request tailored alloy compositions and surface conditions as needed for their processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Copper Cut Wire Shot Category

Cut Wire shot

Price 650 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Other, Cut Wire shot

Shape : Other, Many shape

Surface Treatment : Coated

Color : Copper

Industrial Copper Cut Wire Shot

Price 530 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Other, Industrial Copper Cut Wire Shot

Shape : Other, Many shape

Surface Treatment : Coated

Color : Copper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS