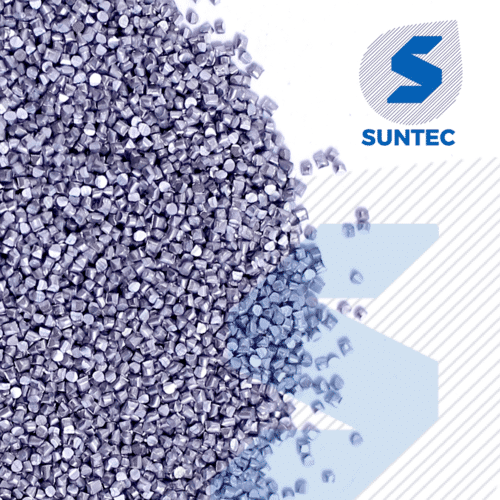

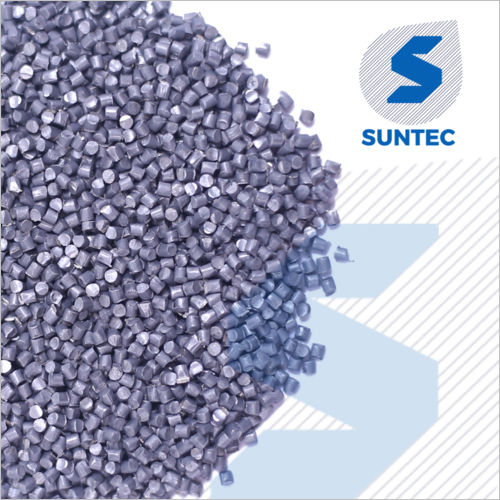

Zinc Cut Wire Shot

Price 360.0 INR/ Kilograms

Zinc Cut Wire Shot Specification

- Surface Treatment

- Power Coating

- Product Type

- Zinc Metal

- Shape

- Many Shape

- Alloy

- Yes

- Strength

- 1650-2050Mpa

- Purity

- 99%

- Color

- Purple

Zinc Cut Wire Shot Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- FOB Port

- Faridabad , Haryana

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 7 Months

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Standard

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Zinc Cut Wire Shot

We manufacture Zinc Cut Wire Shot (Zinc Shot) as per VDFI 8001 suitable for use in deburring, deflashing, and general cleaning of light metal castings and other non ferrous products. Our products reduce wear and tear on blast equipment compared to most other metallic abrasives and creates less dust. Zinc Cut Wire Shot will not damage soft-alloy cast parts and in most cases, parts need no other cleaning prior to a plating process. A thin film of zinc deposited onto cast parts which will temporarily protect parts from corrosion. We can produce these shots with many diameters, and we can also produce according to customers requirement.

|

ABRASIVE |

ZINC CUT WIRE |

|

CHEMICAL COMPOSITION |

Zn 99.99% or up |

|

|

Fe 0.005% or less |

|

HARDNESS |

36-51 HV |

|

AVAILABLE SIZE |

0.6 x 0.6 mm |

|

|

0.8 x 0.8 mm |

|

|

1.0 x 1.0 mm |

|

|

1.2 x 1.2 mm |

|

|

2.5 x 2.5 mm |

|

|

3.0 x 3.0 mm |

Technical details

|

Brand |

Suntec Enterprises |

|

Packaging Type |

Packet |

|

Material |

Zinc |

|

Size |

0.30-3.17mm |

|

Hardness |

36-51 HV0.2 |

|

Minimum Order Quantity |

1000 Kilogram |

Precision Engineering for Optimal Performance

Our Zinc Cut Wire Shots are crafted using advanced technology and strict quality control procedures, ensuring each batch meets high standards of strength and purity. The powdered coating enhances resistance and longevity, making them a preferred choice for industrial surface applications.

Versatile Applications Across Industries

Thanks to their unique properties and multiple shapes, these Zinc Cut Wire Shots can be used in various processes, from surface cleaning to shot peening, across automotive, aerospace, and machinery manufacturing sectors. Their adaptable design makes them suitable for demanding environments.

FAQs of Zinc Cut Wire Shot:

Q: How are Zinc Cut Wire Shots manufactured with such high purity and strength?

A: Our Zinc Cut Wire Shots are produced from high-grade zinc alloy with 99% purity. The manufacturing involves cutting zinc wire into uniform shapes, followed by precise power coating. Rigorous quality checks ensure strength levels between 1650 and 2050MPa, meeting industrial standards.Q: What are the primary uses of Zinc Cut Wire Shot in industry?

A: Zinc Cut Wire Shots are mainly utilized for cleaning, deburring, and surface finishing of metal components. Their strength and surface treatment capabilities make them particularly effective for shot peening and preparing surfaces for coating or painting.Q: When is zinc wire shot preferred over other abrasive materials?

A: Zinc Cut Wire Shot is ideal when low dust generation, minimal wear on equipment, and superior corrosion protection are required. Its non-ferrous composition is advantageous in applications sensitive to rust or iron contamination.Q: Where can Zinc Cut Wire Shot be supplied from?

A: As an exporter, manufacturer, and supplier from India, we deliver Zinc Cut Wire Shots both domestically and internationally. Our distribution network ensures timely delivery to various industries worldwide.Q: What is the process for applying power coating to Zinc Cut Wire Shot?

A: The power coating process involves applying a protective layer to the zinc wire shots before or after shaping, depending on requirements. This coating boosts durability and resistance to environmental factors, significantly extending the service life of the shots.Q: How does the purple color and varied shapes benefit the application process?

A: The purple color enables easy identification of shot type, minimizing cross-contamination in multi-blast workshops. Multiple shapes offer tailored impact and surface profiles, ensuring optimal performance across various finishing processes.Q: What benefits does using Zinc Cut Wire Shot offer compared to traditional alternatives?

A: Zinc Cut Wire Shots provide excellent surface protection, reduced dust, and longer equipment lifespan due to less abrasive wear. Their high purity and strength enable consistent results, making them cost-effective and reliable for heavy-duty surface applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zinc Cut Wire Shot Category

Abrasive Blasting Zinc Cut Wire Shot

Price 360 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Alloy : Yes

Shape : Other, Many Shape

Purity : 99%

Color : Purple

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS